The Formation of Nitrosamine Impurities in API and Finished Dosage Forms

A discussion on potential root causes

Organic impurities can originate from various sources and from various phases of the manufacture of API and the preparation of pharmaceutical dosage forms. The impurities formed may be the result of the synthesis pathway, overall manufacturing processes, or degradation products.

The differentiation between synthesis-related impurities, process-related impurities, and/or degradation products is not always possible. There may be several possible synthetic routes for the preparation of the same AP, especially when it comes to generic drugs. Degradation products may be formed during the synthesis and isolation of the end-product API. Degradation products may also form during storage of the API, and especially during formulation and storage of the finished dosage form. Furthermore, impurities not previously identified may subsequently be found as measurement technologies improve, with improvements in analytical sensitivity resulting in the ability to measure at even lower levels.

The differentiation between synthesis-related impurities, process-related impurities, and/or degradation products is not always possible. There may be several possible synthetic routes for the preparation of the same AP, especially when it comes to generic drugs. Degradation products may be formed during the synthesis and isolation of the end-product API. Degradation products may also form during storage of the API, and especially during formulation and storage of the finished dosage form. Furthermore, impurities not previously identified may subsequently be found as measurement technologies improve, with improvements in analytical sensitivity resulting in the ability to measure at even lower levels.The discovery of theretofore unknown organic impurities as a result of improvements in analytical sensitivity from synthesis pathway, the overall manufacturing process or degradation products is not new. Over the years, a number of API and finished dosage forms have been the subject of the discovery of the presence of unknown organic impurities of potential concern, whose discovery was made possible by improvements in analytical sensitivity. Consequently, the discovery of nitrosamines, and the potential toxicological concerns and impact, in specific API and finished dosage forms at very low levels has been made possible by these improvements.

Since the 1950s, nitrosamines in food have been of interest, particularly due to their potential carcinogenic properties. Nitrosamines and/or their precursors can be found in a diverse range of products such as processed meats, alcoholic beverages, cosmetics, elastomers, cigarette smoke, and, more recently, in drug products. They can also form in the mouth or stomach if the food contains nitrosamine precursors. Under the acidic pH in the mouth or stomach, nitrite or nitrates added to food or naturally occurring may combine with any amines present to form nitrosamines.

There are five (5) potential root causes for the formation of nitrosamine impurities in API and finished dosage forms. These include:

- Synthesis pathways

- Raw materials, recycled solvents, reagents, and catalysts

- The quenching process

- Process optimization

- Storage conditions of the API and finished dosage form

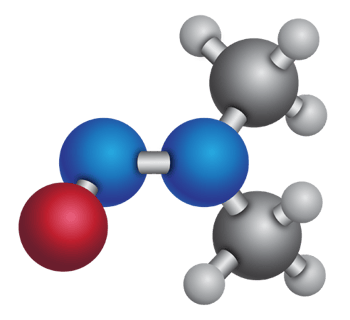

Nitrosamine formation is possible in the presence of secondary, tertiary, or quaternary amines and nitrite salts under acidic reaction conditions. There is a greater risk of nitrosamine formation if nitrous acid is used to quench residual azide in the presence of precursor amines. Nitrites used as reagents in one step can carry over into subsequent steps and react with amines to generate nitrosamine impurities. When present, nitrite salts can carry over to subsequent steps and react to generate nitrosamine impurities.

Synthesis Pathways

In general, processes that use nitrites in the presence of secondary, tertiary, or quaternary amines are at risk of generating nitrosamine impurities.

In general, processes that use nitrites in the presence of secondary, tertiary, or quaternary amines are at risk of generating nitrosamine impurities.

Nitrosamine impurities can be introduced from vendor supplied materials, including starting materials and raw materials, which are contaminated. For example, sodium nitrite is a known impurity in some starting materials and when present, can react with amines under acidic conditions to form nitrosamines. Other nitrate-containing raw materials, such as potassium nitrate, may contain nitrite impurities. Fresh solvents like toluene may contain secondary or tertiary amines as impurities.

Raw Materials

Nitrosamine impurities can be introduced from vendor supplied materials, including starting materials and raw materials, which are contaminated.

Nitrosamine impurities can be introduced from vendor supplied materials, including starting materials and raw materials, which are contaminated.

Recycled/recovered solvents, reagents, and catalysts may pose a risk of nitrosamine impurities due to the potential presence of residual amines, such as trimethylamine or diisopropylethylamine. Where the recovery process involves a quenching step, as with nitrous acid used to decompose residual azide, nitrosamines may form during solvent recovery. These nitrosamines may be entrained, thus further increasing the risk of contamination in material recovery.

Recycled Solvents, Reagents, and Catalysts

Residual amines, such as trimethylamine or diisopropylethylamine are a cause for concern.

Residual amines, such as trimethylamine or diisopropylethylamine are a cause for concern.

When a quenching step is performed directly in the main reaction mixture, such as when nitrous acid is added to the reaction mixture to decompose residual azide, formation of nitrosamines can occur. This step results in nitrous acid coming into direct contact with residual amines in the raw materials used in the manufacturing process. With the nitrosamine impurities formed being carried to subsequent process steps. If there are not adequate removal or purification operations in place, or the process optimized for removing specific impurities of concern, the entire downstream process can be contaminated with nitrosamines.

Another potential source of formation of nitrosamine impurities involves the control of critical process parameters such as temperature and pH, and the sequence of adding reagents, intermediates, or solvents. When there is a lack of optimization or poor control of the manufacturing process for these parameters, conditions favorable to the formation of nitrosamines can exist. Failure to effectively control these parameters can result in widely varied conditions resulting in different nitrosamines in different amounts across batches from the same process with contamination detected in some batches but not others.